Accidents can happen at any time in the workplace. For example, you slip with a knife or a sharp object slices your hand. This can lead to a serious cut… or worse. Only then do you realise how vulnerable our hands really are.

Fortunately, cut-resistant gloves protect the hands and wrists from common risks, such as cuts, abrasions, and punctures.

But which gloves should you buy? In this beginner's guide, you will learn how to choose the best cut-resistant gloves for your application.

- Standards

- Choosing liners

- Coatings

- Comfort

- Conclusion

What are cut-resistant gloves?

Cut-resistant gloves protect your hands and wrists from the risks of sharp objects, such as cuts and puncture wounds. These are made of a synthetic material, such as Kevlar, Dyneema, HPPE (polyethylene), or fibreglass.

Some gloves are better in dry conditions, while others provide extra grip on slippery surfaces.

The type you need to protect your staff's hands depends on their type of work.

The most important selection criteria

There are four important criteria you need to consider when buying cut-resistant gloves.

Cut resistance is important when making your choice. But also assess the fit, the lining, and the coating that determines the grip. These features are essential in certain situations.

Cut-resistant gloves: standards

Gloves have different properties, such as liquid proofing, heat resistance, and cut resistance. European standards have been established for all such properties.

After testing, gloves are rated in accordance with these standards. Two standards are important for the cut resistance of gloves: EN 388 and ISO 13997.

These primarily tested the 'mechanical properties' of gloves, including cut resistance.

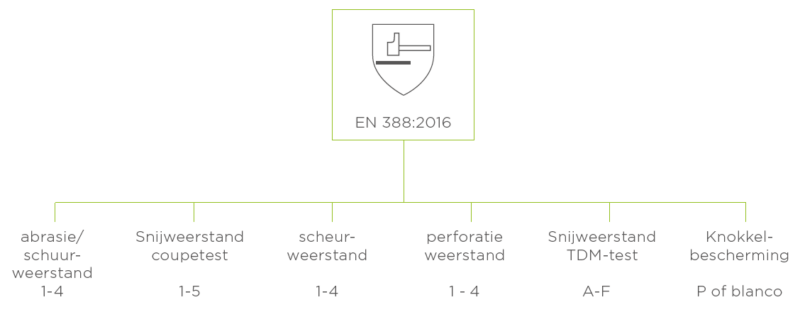

EN 388:2016

Make sure you examine the EN 388 standard for cut-resistant gloves. Once tested, the cut resistance of gloves is rated between 1 and 5. The higher the value, the better the glove protects against cuts.

This value is determined using the coup test. The EN 388 coup test measures the number of cycles over a short distance required to cut through a glove versus a reference material.

| Value | Number of cycles |

|---|---|

| 1 | Minimum 1,2 cycles |

| 2 | Minimum 2,5 cycles |

| 3 | Minimum 5 cycles |

| 4 | Minimum 10 cycles |

| 5 | Minimum 20 cycles |

ISO 13997

In addition to the EN 388 standard, another test method is often used to measure the cut resistance of gloves: ISO13997, also known as TDM.

This is an additional test that is done for 'highly' cut-resistant gloves. It is required for cut-resistant materials that blunt knives during the coup test.

The score is given in classes from A to F and represents the number of Newtons required on the blade to cut through the specimen.

| Class | Newton |

|---|---|

| A | 2 Newtons |

| B | 5 Newtons |

| C | 10 Newtons |

| D | 15 Newtons |

| E | 22 Newtons |

| F | 30 Newtons |

Choosing liners

You should also assess the material used to line the gloves.

Each type of fibre has properties that determine which glove is the best choice for your staff. Often the lining is a combination of the fibres listed below.

Aramid

Looking for a glove with medium cut resistance? Then a specimen lined with the material aramid is a very suitable choice. Well-known brand names are Kevlar and Twaron.

A lining made of this material is resistant to heat, but less resistant to abrasion and UV radiation.

Cut resistant gloves with aramid lining

HPPE

When the gloves do not need to be heat-resistant, a liner made of HPPE is a very suitable choice. HPPE is a material based on polyethylene.

Like aramid, HPPE has medium cut resistance. The wearing comfort is also good. Furthermore, HPPE offers sufficient resistance to abrasion.

Cut-resistant gloves with HPPE

Dyneema Diamond®

Do you need the gloves to be lightweight and elastic around the hands because staff must wear the gloves for a long time? But do these also have to be 'guaranteed cut resistance'? Then Dyneema Diamond is a good choice. This material also makes gloves more durable as these last longer.

No fibreglass is used in the construction of Dyneema Diamond: no compromises are made in terms of cut resistance.

Cut resistant gloves with Dyneema Diamond

Fibreglass

Fibreglass makes other liner fibres more resistant to cuts. A liner is usually not made of just fibreglass.

The disadvantage of fibreglass is that it can break when the glove is used for a long time. If that happens, the cut resistance of the glove may be lowered.

Stainless steel

For certain tasks, gloves with a very high cut resistance are necessary to work safely.

The material stainless steel is then suitable for the lining, especially if it is mixed with HPPE or fibreglass.

However, like fibreglass, stainless steel can break and become less resistant to cuts.

The wearing comfort of a glove lined with stainless steel is average. So, it is less suitable for wearing the entire workday.

Coatings of cut resistant gloves

When buying gloves, also pay attention to the coating.

The raw material of the coating determines the glove's grip, among other things. Do you work with a slippery liquid, such as oil? Then you need gloves with an exceedingly good grip to prevent sharp objects from slipping out of your hands.

In other working conditions, a supple coating is particularly important.

The most common coatings used on cut-resistant gloves and the properties of each material are listed below.

Polyurethane (PU)

Gloves with a polyurethane coating are thin, flexible, and breathable.

This type of coating provides a good, dry grip, and resists abrasion. A PU coating is ideal for drier applications where no oil is used.

Nitrile and nitrile foam

Thanks to a nitrile coating, the wearer of the glove has an excellent grip when working with liquids such as oil and grease.

This material prevents liquids from passing through the glove and making the hands moist.

Nitrile foam promotes the grip required for safe handling of slippery objects. Both of these coatings are combined in some gloves.

A nitrile (foam) coating provides good protection against cuts and perforations.

Latex

Latex coatings are often used in gloves that require very good abrasion resistance.

This coating is also very suitable for winter gloves thanks to its water-repellent properties.

Latex is less suitable in contact with oil or grease.

The comfort of cut resistant gloves

Comfort is also a factor to consider especially when your employees wear cut-resistant gloves for a long time. You want to prevent them not wearing protective gloves because they are uncomfortable.

Of course, everyone experiences comfort in their own way. In general, the sensitivity of the fingers and the breathability of the material have a major impact on comfort.

Finger sensitivity

Gloves should be (extra) finger-sensitive, for example, when working with fine tools or small parts.

In recent years, you increasingly see finger-sensitive gloves in combination with a higher level of protection.

This enhances the comfort of the glove.

Breathable feeling

It is pleasant if gloves breathe well especially when wearing them for long periods of time. Perspiration can also escape better, which prevents a clammy feeling.

The material of the coating especially determines the breathability. The lighter the coating, the more comfort you will experience.

However, the temperature in each glove eventually rises, so sweating can never be completely avoided.

Touch screen

Operators often have to use screens in the workplace. Or they must use a smartphone. At the same time, their hands must also be protected.

When this is the case, look for gloves with a touch screen property so that your staff can operate screens without danger.

Cut resistant gloves with touch screen property

Hand protection and sustainability

Sustainability is gradually finding its way into the glove world.

For example, gloves with linings made from recycled materials or which are currently produced from raw materials of natural origin are already available today.

In a nutshell

Each situation or task requires a different cut-resistant glove. Closely examine the cut resistance in the EN 388 and ISO 13997 standards, but try not to overprotect either.

The lining you choose determines the cut and abrasion resistance, while the coating determines the grip of your gloves.

Finally, the comfort of your cut-resistant glove is an important part of the selection process. Before you buy, first have your staff test the gloves. After all, they know better than anyone the difference between a basic and a premium glove.

Order cut resistant gloves

See the full range of cut resistant gloves and filter according to your needs for coating, linings, and key properties.

At Vandeputte, you will find suitable work gloves for every task and work situation.