Welders play a crucial role in a huge range of industries, varying from the metal industry and construction to the food sector. Welding tasks vary in terms of size, method, material types and thickness, etc. What all methods and techniques have in common, however, is an exposure to several health risks.

In this article, we will take an in-depth look at these risks and how welders can protect themselves.

The hazards from welding fumes

Welding fumes are a blend of solid particles and gases. The fumes can encompass visible particles, the size of grains of sand, as well as microscopic particles that can be breathed in easily. Exposure to welding fumes and other gases that are released during welding can lead to very serious health complaints. Welding fumes are also rightly defined as carcinogenic.

The type and quantity of welding fumes and gases to which welders are exposed depend on several factors:

- the materials used

- the welding process

- the power supply

- the welding electrode used

In order to assess the hazards according to national safety standards, it is vital to consult an expert.

How can you identify the health risks for welders?

Identifying respiratory risks for welders is vital in order to maintain good health. Here are a few symptoms that could point to repeated exposure to welding fumes:

Health problems in the short term

- Irritation of the eyes, nose and throat

- Dizziness

- Metal fume fever: Flu-like symptoms that occur soon after exposure, are usually short in duration and clear up quickly. This includes a high fever, cold shivers, pain, vomiting, weakness and tiredness. It is worth noting that these symptoms often occur on Mondays, after a few days without any exposure.

- Nausea

- Headaches

- Lung infections

Health effects in the long term

Illnesses as a consequence of welding fumes often develop over many years and can lead to:

- Chronic obstructive pulmonary disease (COPD): This is a serious condition which leads to breathing difficulties.

- Pneumoconiosis and lung fibrosis: these conditions are the result of long term exposure to damaging fumes and can lead to the formation of scarring in the lungs.

- Work-related asthma

- Pulmonary function disorders: including bronchial asthma, chronic obstructive pulmonary disease (COPD) and lung cancer.

- Increased risk of heart attacks and strokes

- Laryngeal cancer and urinary tract cancer

- Stomach ulcers, kidney damage and damage to the nervous system

Did you know? Welders have the same risk of chronic bronchitis as regular smokers and a 40% higher risk of lung cancer than non-welders.

Choosing the right protective equipment

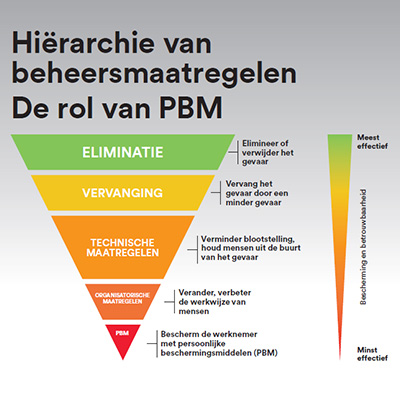

Choosing the right protective equipment is vital in order to protect the health of welders. The hierarchy of controls can provide a guiding principle when limiting the exposure to welding fumes. Measures at the top of the list are regarded as the most effective.

Download the overview of three types of respiratory systems

Hierarchy of controls

Want to find out more? Working at height: the importance of prevention hierarchy

Did you know? Ineffective respiratory protection is the third most common violation in the workplace.

Overview of metals, welding processes and respiratory protection

Download the overview and read more about welding techniques and ventilation conditions. There is also a review of the types of respiratory protection a safety expert would recommend on the basis of the risk assessment.

Download the overview of metals, welding processes and respiratory protection

Choosing the right respiratory protection

Selecting the right dust mask or appropriate respiratory protection is crucial and must be based on specific working conditions. Here are a few options:

- Disposable masks: These masks are suitable for short periods of exposure to welding fumes and other fine particles. They are easy to wear and should be thrown away after use.

- Reusable masks: For welders who are regularly exposed to welding fumes, reusable masks are a more sustainable option. These can be cleaned and used again after use.

- Motorised respiratory systems: A motorised respiratory system is the best choice if welders must work for long periods in conditions which include substantial welding smoke. This system provides a continuous supply of air and protects welders against inhalation of damaging vapours/smoke. Want to find out more? The 10 biggest strengths of Speedglas G5-01

- Respiratory system with supplied air: In some conditions, where the air is extremely contaminated, a respiratory system with supplied air may be the most suitable option. This system provides welders with clean, breathable air, independently of the surrounding air quality.

Did you know? In the UK, every year, 40 to 50 welders are admitted to hospital due to lung conditions caused by welding fumes.