Hands are fragile, which is why it is vital to use good protective gloves to protect your employees against chemical substances.

Unfortunately, a glove that protects you from any chemical while being flexible and comfortable does not yet exist. Moreover, it can be quite difficult to know which glove you need for a particular application or chemical.

Following these 4 steps will make that process a lot easier!

- Step 1: Look around at your environment and assess the possible risks

- Step 2: Choose the right material

- Step 3: Performance and comfort

- Step 4: Choose the right size

Step 1: Look around at your environment and assess the possible risks

Primary hazards

Start by looking at the working environment and the risks to your employees.

What substances or products would they come into contact with in the event of leakage, splashes or other accidents?

How often will they come into contact with the chemical?

Above all, it is important that you always match a glove to a specific task and do not use it for other applications. Every glove and every application is different.

The most common factors that influence your choice are:

- Which chemicals you use (acids, bases, solvents, etc.)

- The concentration and toxicity of the chemical.

- How long and how often you will come into contact with the chemical.

- In what way your employees come into contact with a chemical (splashes, blasting, dipping, etc.).

- The length of your glove.

- Finger sensitivity, grip and comfort.

- Size of the glove.

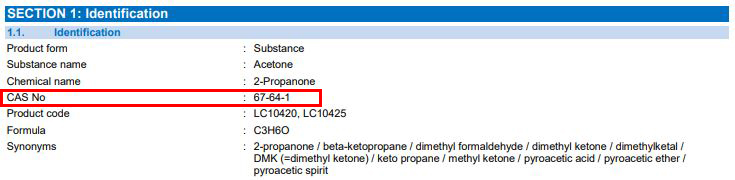

A good place to start your search is by looking at the MSDS (Material Safety Data Sheet). Here you will find instructions on what protection to wear, and if all goes well, the CAS number (unique numerical identifier of chemical elements) of the chemical's.

Save the CAS number, you will need it in step 3.

Secondary risks

Chances are that you won't need only chemical protection. Applications are so varied that you also have to take the secondary risks into account.

Perhaps your employees work with sharp objects. In which case, gloves must not only protect against chemicals, but also be cut resistant (EN 388).

If there is contact with naked flames or hot objects, choose gloves that offer additional protection against heat and fire.

In fact, if you operate in the food industry, make sure your gloves are also food approved.

Step 2: choose the right material

Now that you know which substances your employees (could) come into contact with, including the risks, you can match this information to the best material for the gloves.

Glove materials have specific properties that make them very suitable for one particular working environment, but less so for another

Below you will find the most common materials and their most important properties:

- PVC

- Latex

- Nitrile

- Neoprene

- Butyl

- Viton

PVC (Polyvinyl Chloride)

PVC is a perfect choice for various workplaces because of its excellent price-quality ratio.

These gloves are very suitable for working with acids and alkalis, and are ideal for service and maintenance work in a wet environment.

They are also a good choice for people who work with substances such as hydraulic oil, aromatic solvents or alcohol.

PVC gloves provide very good grip and are abrasion resistant.

However, if you are looking for protection against organic solvents, it is better not to choose PVC. Moreover, this is not a suitable material for hot environments, because of its poor heat resistance.

Suitable industries and applications:

- Fisheries

- Maintenance

- Mining

- Fuel and oil

- Mechanical work

- Construction

- Petrochemicals

Latex

Latex gloves can be used to protect against various aqueous chemical solutions:

- Nitric acid

- Sulphuric acid

- Methanol

- Formaldehyde

- Sodium hydroxide

- Acetic acid

They are extremely supple and therefore comfortable to wear. They are also highly resistant to sanding and cutting risks.

The cut and abrasion resistance is high, so they are especially suitable for employees who work with sharp objects at the same time.

However, some people are allergic to latex. Check this before ordering these gloves for your colleagues.

Latex gloves are less suitable when working with mineral solvents or oils.

Suitable industries and applications:

- Laboratories

- Agriculture

- Pharmaceutical industry

- Food industry

Nitrile

Nitrile is perfect if you want to combine the advantages of latex and PVC. It protects you from perforations and abrasions.

Nitrile is highly suitable if you need protection against solvents, bases, thinners and esters. These gloves are recommended for work such as preparing and applying paint and varnish, or treating and finishing timber.

It is widely used in the food industry so you can safely handle different foods.

The disadvantage of nitrile is that it can be less flexible. Some people also suffer from allergies, but less so than with latex.

Suitable industries and applications:

- Food industry

- Paint

- Timber finishing

- Automotive

- Industrial cleaning

Neoprene

If you often work with petroleum-based products, fats or fuel, then this is a good choice. It also offers excellent protection against acids and alkalis.

It is a smooth, abrasion and cut-resistant material with heat-resistant properties.

One big disadvantage: when neoprene gets wet or damp, it loses its grip.

Suitable applications and industries:

- Industrial cleaning

- Chemical treatment of metals

Butyl

A butyl glove is the gas and ketone glove par excellence. The reason for this is that it has a dense molecular structure.

It is supple, elastic and protects the wearer's hands very well against esters, ketones, aldehydes and alcohols. Also, in the military sector, butyl is used against chemical warfare gases.

Butyl does have a few disadvantages: it is quite expensive because of its very high and specific chemical protection.

Viton

Viton provides a very specific chemical protection and is therefore also the most expensive material.

Viton was developed for the aviation industry because of its extreme chemical protection and heat resistance.

Are you looking for gloves that protect against benzene, toluene and PCBs (Polychlorinated Biphenyl)? Then choose Viton.

Step 3: protection and comfort

Now that you know the advantages and disadvantages of the most common materials, you should already have a good idea of which type of glove you need.

In this step, we will look in greater depth at the levels of protection and comfort.

Performance

Each glove manufacturer has a permeation table, which you can use to make a link between tested chemicals (using the CAS number) and their gloves and/or coatings.

In this table you will find three important things that are extensively tested for the EN 374 safety standard:

- Breakthrough time

- Protection index from 1 tot 6

- Degradation (expressed as percentage)

Breakthrough Time

The speed at which a chemical substance, at molecular level, can penetrate a glove. The counter stops when a quantity of 1.0 µg/cm²/min is reached.

The result is the number of minutes. The higher the result, the longer it takes to reach this speed.

It may be possible that, although a chemical has penetrated, the rate of permeation has not yet been reached. This dormancy effect is harmful in the long term with extreme toxins.

Protection index

This index shows the permeation rate of a glove that protects against various chemicals.

The higher the index, the longer the breakthrough time and the better your gloves will protect.

| measured breakthrough time | protection index |

|---|---|

| 10 minuten | 1 |

| 30 minuten | 2 |

| 60 minuten | 3 |

| 120 minuten | 4 |

| 240 minuten | 5 |

| 480 minuten | 6 |

Degradation

The physical changes to your glove. For example, your glove may become stiffer, swell, or even change colour after use.

The result is a percentage (positive or negative). A positive result means that the material has softened, negative means a hardening.

Now it is time to find your CAS number and look in the table for breakthrough time, protection index and degradation. Some protection tables indicate when a glove is, under certain conditions, suitable, or not suitable for use.

Well-known manufacturers also have a handy online tool into which you can enter the CAS number or the chemical's name. This application then immediately shows you which gloves are suitable, together with their breakthrough time, protection index and degradation.

The chemicals in protection tables and online tools have been tested under laboratory conditions. We recommend that you thoroughly test chemical gloves before using them in practice.

Never use a chemical-resistant glove longer than the tested breakthrough time. From the moment of first contact, your gloves are contaminated and start to permeate and degrade. It therefore makes no sense to add up your minutes over different days.

Replace your gloves as soon as possible if they become contaminated with a chemical.

EN 374:2016

A chemical resistant glove must comply with the EN 374 standard. Some things have changed since 2016. Including the following:

Under the official icon, you will find the code letters of the test substances that range from A to T:

The different types are subdivided as follows:

- Type A: Protective glove with a permeation resistance of at least 30 minutes for a minimum of 6 test substances.

- Type B: Protective glove with a permeation resistance of at least 30 minutes for a minimum of 3 test substances.

- Type C: Protective glove with a permeation resistance of at least 10 minutes for a minimum of 1 test substance.

Tip: Don't use the data of one manufacturer to choose a glove from another manufacturer.

Comfort

Depending on your application, you need to wear gloves for a long or short period of time. Therefore, they should not only protect, but also fit well.

So make a suitable compromise between the finish of the inside, outside and the thickness of your glove.

Inside

If the glove is chlorinated, it is easier to put on and take off. This way, the glove does not need to be made thinner.

Flocked means that the inside is lined with textile fibres for good perspiration absorption. This is ideal for frequent use.

Finally, some gloves have a special knitted lining for additional comfort:

- Cotton provides thermal insulation and absorbs perspiration.

- Polyamide is very fine and seamless for optimal fingertip sensitivity.

- Para-aramid has a very high cut and heat resistance.

- HDPE (High Density Polyethylene) offers resistance to cutting and is very flexible.

Outside

To what extent do you need extra grip in your work?

Smooth gloves are fine for many applications. They also do not mark the objects touched.

Do you need grip in an oily environment, for example? Then choose gloves with a textured surface.

Furthermore, gloves with extra grip are available for working in a wet environment.

Thickness

The thickness of a chemical glove varies from about 0.05 mm to about 2.5 mm.

Most important is the effect on sensitivity and comfort. If someone needs to wear the gloves for a long time, a thicker version is a lot more comfortable. However, be aware that you will want to wear chemical-resistant gloves for as short a time as possible.

How long gloves can be worn has not so much to do with the material, but rather with design.

Step 4: choose the right size

Last but not least: what size should you buy? Too small a size will not allow you to move efficiently, your glove will also wear out faster.

If the size is too large, there is a chance that the glove will fail. Common sizes vary from size 5 to 12.

For the correct size, measure the circumference and length of your hand.

- Lay a tape measure across your knuckles.

- Turn your palm so you see your hand and ensure the tape is across the palm.

- Cross the tape measure so you can see the outline of your palm.

- Check the table to see which size fits your circumference.

| glove size | hand circumference | hand length |

|---|---|---|

| 6 | 152 mm | 160 mm |

| 7 | 178 mm | 171 mm |

| 8 | 203 mm | 182 mm |

| 9 | 229 mm | 192 mm |

| 10 | 254 mm | 204 mm |

| 11 | 279 mm | 215 mm |

Conclusie

Have you completed all the steps? Great! Now you have a summary of all the potential risks, you know the properties of the most commonly used materials and their comfort-enhancing characteristics.

You're all set to choose the correct chemical gloves!