Last update: 17/08/2023

Fall protection inspection is mandatory and the fines are high if you do not have it inspected. Moreover, you obviously want your employees to be able to work safely.

But what do you pay attention to? When must you inspect and maintain fall protection systems? And how often?

This article will teach you more about the maintenance, inspection, and lifespan of fall protection.

Click the link and go directly to your chosen topic.

- When to inspect fall protection

- The difference in Belgium, the Netherlands, and France

- Fall protection inspection in detail

- When to maintain fall protection

- Fall protection maintenance in detail

- Lifespan

When to inspect fall protection?

Every twelve months or after a fall, you must have all personal protective equipment (PPE) for fall protection inspected. This must be done by a competent person in accordance with the manufacturer’s instructions.

This is also stated in EN 365. This standard stipulates all requirements for user manuals and maintaining, periodically inspecting, and repairing fall protection.

Each country transposes this European directive into its national legislation.

PPE for fall protection are products and accessories that are not permanently attached.

These are usually fall harnesses or fall arrest blocks (also known as fall protection devices). But temporary or mobile anchor points, such as ropes or tripods, are also examples of fall protection.

You have your car inspected annually.

So why wouldn’t you want your fall protection inspected to avoid unnecessary risks? The stitching or straps on a harness can fray. This makes it easier for them to tear. An annual inspection reveals such defects.

Proper maintenance extends the lifespan of your PPE and, in addition to the legal obligation, it is also a sustainable investment and much safer for the employees in your company.

The difference in belgium, netherlands and france?

In the Netherlands and France, fall protection can be inspected by a ‘competent person’.

This is a little vague.

We see that many companies have their PPE inspected directly by the manufacturer or the distributor. Only then can you be sure that the right professional will inspect, approve, and repair your goods.

What about Belgium? It’s the odd one out…

Only an approved inspection body is allowed to carry out inspections in Belgium. Such an inspection organ is also known as an External Service for Technical Controls (EDTC).

These companies primarily carry out household inspections, such as EPC inspections.

Industrial companies can also use an EDTC for industrial inspections.

For example, the inspection of lifts, gas installations, and hoisting and lifting equipment. Companies such as Vinçotte or OCB can have all the fall protection approved for your company.

Vandeputte has certified experts who inspect fall protection for Dutch and French companies.

Fall protection inspection in detail

The reason for inspecting fall protection is clear. But what does such an inspection entail? And what exactly are they inspecting?

During the visual inspection, the technician looks at all the things that can pose additional risks when working at heights, such as:

- damage to textile straps caused by cutting, burning, or chemical reactions

- stitching, which has a risk of fraying and abrasion

- notches, deformation, corrosion, etc. in metal parts and buckles

- ropes

- dampers

- the functioning of automatic closures

- the legibility of the identification label (year of manufacture, serial number, etc.)

It’s important that you know what’s happening. The test report will show you what work has been carried out and the points of the test that were pass or fail.

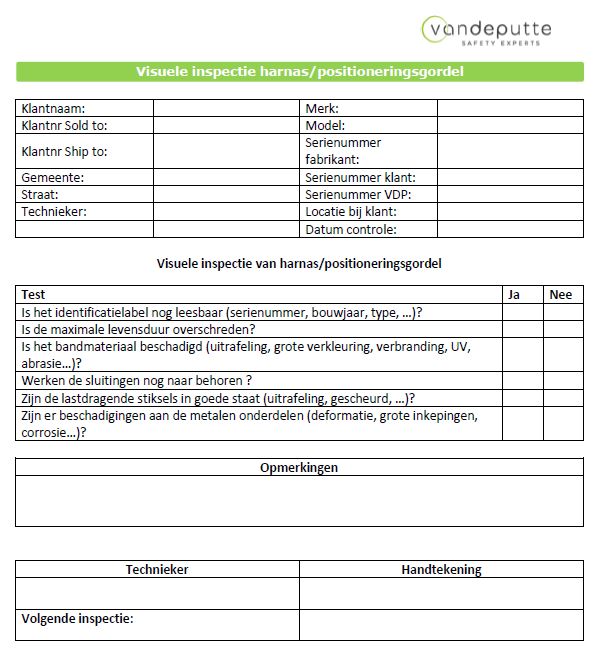

This is what it looks like (Dutch version):

When to maintain fall protection

Naturally, it is also important to know when it is time for a thorough servicing of your equipment.

Be sure to have your equipment maintained and/or repaired when necessary:

- the visual inspection shows that a PPE for fall protection no longer meets the criteria. Usually, this is safety equipment made of stainless steel/metal without a specific lifespan (e.g. fall arrest blocks or tripods);

- the manufacturer prescribes that the inside of a fall arrest block must be checked preventively at certain intervals;

- a fall arrest block is used outside. The manufacturer may not prescribe fixed deadlines for this. But even then, it is better to check the inside every year.

If you use your fall protection equipment intensively, then make a good habit of inspecting your equipment yourself a couple of times a year.

Fall protection maintenance in detail

People who maintain and repair fall protection are trained by one or more manufacturers.

During the maintenance of fall protection and/or the repair of a fall arrest block, for example, they go through a few steps:

- open the fall arrest block;

- visually inspect the brake shoe, spring, brake hooks, cable, and housing, among other things;

- preventive and curative maintenance: for example, replacing a cable or spring;

- drawing up a maintenance report;

- registering the fall arrest block based on the existing identification label;

- entering the work carried out into the database;

- inspection by an EDTC to confirm the work carried out (only in Belgium).

The maintenance or repair of fall harnesses or positioning belts is not often carried out in practice.

You cannot do anything about fall harnesses with torn straps or broken closures.

They often cannot be repaired or the repair costs are higher than just purchasing a new one.

The takeaway message: buy new ones!

Lifespan

Each brand gives a different lifespan to its fall protection PPE. Make it a good habit to have every safety device visually inspected in due time.

Regular inspection yourself is also a must.

There are a few rules of thumb for the lifespan of fall protection equipment:

| material fall protection | example | lifespan |

|---|---|---|

| Metal, metal or stainless steel cables | Fall protection devices | Unlimited |

| Belting materials | Fall harness | Average of 10 years |

Conclusion

Falling from height remains one of the most common risks in the workplace.

Regular maintenance and inspection rule out any additional risks. Moreover, you don’t have to spend money unnecessarily buying new products because they last longer.

Have your fall protection PPE inspected at least once a year and after every fall incident. In this way, you are legally compliant and demonstrate that you are truly concerned about the safety of your employees.

Maintenance and repair of your PPE and technical products / maintenance-sensitive products

The correct functioning of PPE and technical products is crucial for the safety of your employees. Therefore, our experienced technicians provide comprehensive maintenance and repair of your maintenance-sensitive products to prolong their lifespan and prevent possible breakdowns.

Discover our Maintenance & Repair

Also read :